October 25, 2022 - by Santina Russo

Germany still operates more than 130 coal-fired power plants. Switzerland: none. France has 17 gas-fired power plants and is planning a series of new small nuclear power plants. Switzerland: zero gas and zero planned nuclear plants. Instead, Switzerland has the water supply from the glaciers in the Alps and a decent amount of rain feeding rivers and storage lakes for its hydroelectric production — Switzerland’s priceless bonus in clean energy. However, even the traditionally reliable production of energy from water must now change: Especially small and medium hydropower plants must become more flexible with the seasons, usage cycles, and overall demand increases impacting Europe.

Flexibility suddenly matters

Firstly, hydroelectric power must be able to better handle seasonal fluctuations. “Especially run-of-river power plants are directly dependent on a river’s water discharge,” says Cécile Münch-Alligné, a professor at the Institute of Sustainable Energy of the School of Engineering at HES-SO in Valais, Switzerland. “Until now, during winter, water quantities have at times been too low to operate some plants’ turbines.” Secondly, a new tariff system in Switzerland encourages small plant owners to better adapt their energy production to the needs of the market. Since 2018, it rewards electricity produced at times when it’s needed most with much higher prices than when it’s needed less — in contrast to before when the feed-in-tariff was the same no matter of the time of day. This means that before, plant operators could produce electricity when river conditions were most favourable; while now, they must adjust to the market. And lastly, timely energy production to meet peak energy needs will help to contain the energy crisis that, according to many experts, awaits us this winter because of the Russian aggression in Ukraine.

“This increased adaptability is not a trivial requirement, since a flexible operation will have consequences on the residual lifetime of the Pelton turbines used in most alpine hydropower plants,” explains Cécile Münch-Alligné. With simulations run on CSCS’ supercomputer “Piz Daint”, she and her team recently investigated if and how medium and small hydropower plants can still be operated flexibly to adapt to the electricity needs of the moment.

One of many similar Swiss hydropower plants

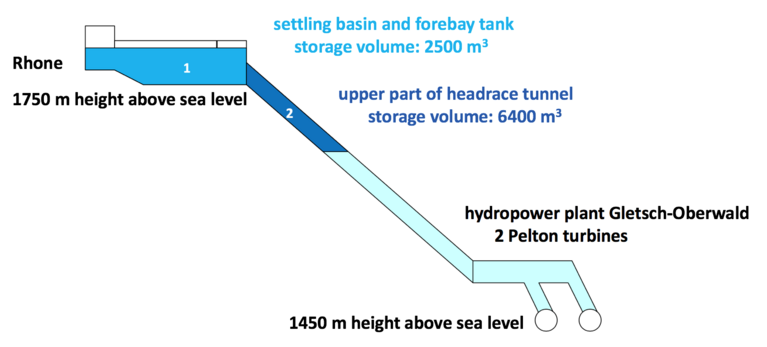

The team based their simulations on the Gletsch-Oberwald facility in the Swiss canton Valais. This run-of-river power plant uses water from the Rhone river, fed by the Rhone glacier. It is equipped with two six-jet Pelton turbine units, producing a maximum power of 7 MW each. The water powering them is guided through a settling basin and then through a pressure tunnel called the headrace channel, down to the turbine units 300 metres below. This height difference and the potential energy that it holds — called “head” in technical terms — is where the harvested energy comes from.

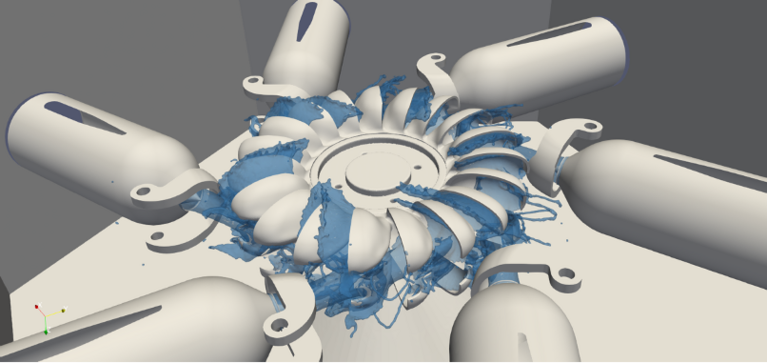

At the bottom of the channel, the water stream is guided through a circular distributor duct into injectors, where it gains speed to more than 270 kilometres per hour before then being released on the turbine runner. The runner itself is a sort of high-tech water wheel that transforms the hydraulic energy into mechanical energy, which is then transformed into electricity by a generator.

This way, the power plant produces around 40 GWh of electricity per year — enough to machine wash 40 million loads of clothes or watch 40 billion hours of television. Yet, the plant could not always generate the maximum amount of energy. If the Rhone’s water flow was too low, the turbines had to be shut down completely, which is highly unfavourable: Not only is no energy produced at times, but frequent stops and starts are harmful to the turbines, lowering their life span. However, as Münch-Alligné explains, keeping Pelton turbines operational on lower water levels is risky as well: “Especially the runner geometry is specifically designed for a given head. If it changes, the water jet feeding the runner will change as well, and this can result in hydrodynamic instabilities that can cause vibrations and fatigue on the turbine components.” The goal of Münch-Alligné’s simulations was therefore to predict the influence of head variations on the water jet and the torque of the runner.

Capturing complex physics

“The physics of the water flow in a Pelton turbine is complex,” says Münch-Alligné. On the one hand, it involves a so-called single-phase internal flow inside the distributor and the injectors, where only water and no air is present and pressure is high. On the other hand, at the outlet of the injectors, this suddenly changes with the water now undergoing a velocity boost and having air contact. “The exiting water jet being very fast, while the surrounding air has no velocity at all, causes intricate hydrodynamic instabilities at the surface of the jet, making it challenging to capture its flow correctly,” Münch-Alligné explains.

Her team handled this intrinsic complexity by combining two different methodologies. For the flow within the distributor and injectors, they used a Navier-Stokes solver provided by the OpenFOAM toolbox, which is ideal for pressurized flows of only one phase — in this case, water with no air contact. In a second step, they employed GPU-SPHEROS, a code developed at EPFL in Lausanne, for the free flow from the injectors to the runner buckets using the results of the previous OpenFOAM simulations as input values.

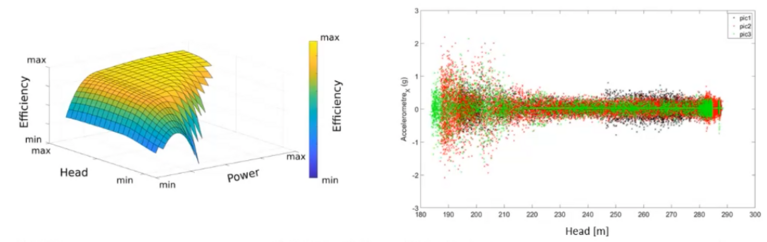

The team simulated 12 different turbine operating conditions, varying the head, and the opening of the injector nozzles that adjust the quantity of water feeding the runner. The simulation results showed that the head can be lowered substantially using adapted nozzle openings, until suddenly, the turbine's efficiency decreases in a sharp drop. “At the same time, vibrations on the runner increase substantially,” recounts Münch-Alligné, “resulting in very unfavourable conditions for the machinery.”

From simulations to real-life operation

The simulation results provided the scientists and the plant’s owners with a landscape of predicted favourable and unfavourable turbine operating conditions. These were then confirmed by real-world measurements of the Gletsch-Oberwald Pelton turbines. Specifically, the simulation results showed that the turbines can safely be operated with a head value as low as 210 metres — a reduction of around 30 percent compared to the standard head of 288 metres for this plant. For practical use, the plant owners added another safety margin so that in the future, they plan to use heads as low as 230 metres,” says Münch-Alligné. According to the owner’s estimates, this flexible use when water levels are low more than doubles the plant’s energy production in winter.

In principle, these simulation results can be transferred to a further 175 hydropower plants within a range of performance between 1 and 30 MW. Cécile Münch-Alligné herself is planning to perform similar studies on around 30 other hydropower plants in the Goms region of the canton Valais — again, to establish if and how the plants can safely be operated with flexible heads. In addition, she plans to collaborate with manufacturers to investigate different runner designs in the future to find geometries that are not only optimised for a given head, but for a range of configurations and therefore suited for flexible turbine operation.

References:

- Alimirzazadeh S et al.: Numerical simulations of Pelton turbine flow to predict large head variation influence, IOP Conf. Ser.: Earth Environ. Sci. 774 012033 (2021), https://iopscience.iop.org/article/10.1088/1755-1315/774/1/012033

- Münch-Alligné C et al.: Production flexibility of small run-of-river power plants: KWGO smart-storage case study, IOP Conf. Ser.: Earth Environ. Sci. 774 012037 (2021), https://iopscience.iop.org/article/10.1088/1755-1315/774/1/012037

This article may be used on other media and online portals provided the copyright conditions are observed.